GN Solids Control is the head quarter of GN Solids America, which is a brand for solids control and waste management equipment and systems born in China and got popular in America since 12 years ago. As a responsible manufacturer, GN Solids Control and GN Solids America won the good reputation by providing clients with high quality equipment and good service.

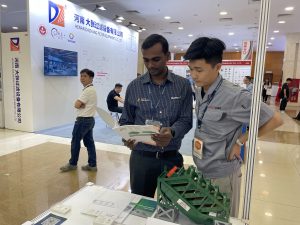

Each year, under name of GN Solids Control and GN Solids America, GN group attends several exhibitions to show the market with GN core products. There are three exhibitions GN always attends during each year, including the CIPPE in Beijing in each March, OTC in Houston in May and ADEPEC in Abu Dhabi in November.

In year 2024, GN Solids America attended OTC showing following equipment:

- Decanter centrifuge GNLW363D. It is a best seller size in oil and gas industry for both solids control and waste management, comparing with GNLW363C, GN has improved some small details and makes the centrifuge more compact in structure. And the GNLW363D resumes to be of high quality with all GN centrifuges’ features as the Duplex stainless steel for the rotating bowl, tungsten carbide tiles for centrifuge propeller protection, SKF bearings and VFD control panels. GN can provide decanter centrifuges together with control cabinets per ATEX, IECEX and etc.

- Drilling mud shale shaker GNZS594J. The shale shaker is used for the first stage of drilling mud treatment in a solids control system, and they are used to remove the largest amount of drilling solids, GNZS594J shale shaker has 4 pieces of shaker screens with a total screen area of 2.74 square meters, and this shale shaker can work at a hgh G force up to 7.5G.

- Solids Vacuum Pump. Vacuum pump is called vacuum because it is driven by air, no need for any electricity. By using an air compressor, it can suck in the material with a negative force and push out the material with a positive force. It is also called solids pump because it can handle material with a high solids content and with large particle sizes.

- GN also showed the shaker screens.

Welcome to contact GN for more information.