**Introduction:**

The recent Vietnam Mining Exhibition proved to be a fruitful endeavor for GN as we connected with numerous valuable clients and industry stakeholders. Our presence at the exhibition showcased our commitment to delivering high-quality mining equipment solutions.

**Engaging with Valuable Clients:**

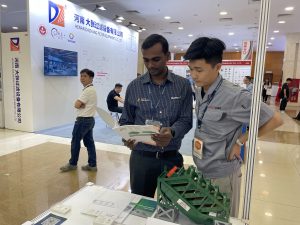

At the exhibition, we had the opportunity to engage with a diverse range of clients from the mining industry. Through insightful discussions and presentations, we were able to understand their specific needs and challenges, laying the groundwork for future collaborations.

**Interest in GN’s Superior Equipment:**

One of the highlights of the exhibition was the overwhelming interest shown by clients in our premium mining vibrating screens and centrifuges. Our reputation for superior quality and performance precedes us, and many clients expressed keen interest in exploring our range of products to enhance their mining operations.

**Looking Ahead:**

The success of our participation in the Vietnam Mining Exhibition reaffirms GN’s position as a trusted leader in the mining equipment industry. Moving forward, we are committed to building upon these promising connections and delivering innovative solutions that drive the success of our clients’ mining endeavors.

In conclusion, the Vietnam Mining Exhibition provided an excellent platform for GN to showcase our expertise and forge valuable partnerships within the mining industry. We are excited about the opportunities that lie ahead and remain dedicated to exceeding our clients’ expectations with our top-notch equipment and services.