In the past week, the yearly IMARC Exhibition was held in Sydney, Australia, it is an well known exhibition in mining industry and attracted visitors all over the world. In this IMARC 2023, GN Separation brought its vibrating screen and tailling dewatering decanter centrifuge to the exhibition and attracted quite a lot visitors. Also, GN’s old clients and friends came to the exhibition, and it is also the first show of GN Australia, the 3rd branch of GN outside China.

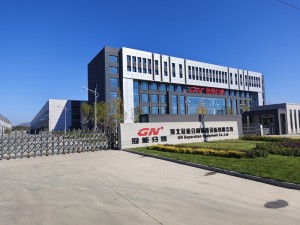

GN Separation was firstly established in year 2007. Although it is a fully private owned company, it developed quite rapidly and soon recognized and became popular in the market all over the world. In year 2013, GN started its own branch company in Houston, USA, which was the first solids control brand from China who settled in USA. In year 2016, GN set up the 2nd factory in China, in the same industry zone of the 2st factory, in order to increase the producing capacity for matching clients’ need. And in year 2023, GN Australia was established in Queensland and GN’s new factory, a modern and large facility with 80000 square meters area has been put into use. In this new factory, GN has large blanking machines and welding robots for fabricating. Both this mining vibrating screen and the decanter centrifuge shown in IMARC are manufactured there, origin from GN, China.

1.Mining Vibrating Screens: Mining is one of the 3 industries GN’s products are applied for, along with oil and gas and environment protection. Mining vibrating screens are one of the core products GN provided for mining industry. GN offers the full range of vibrating screens including the high frequency fine screening screens of single deck and stack sizers, middle sized vibrating screens for classification and dewatering, and large vibrating screens like flip-flow screening and banana screening.

2.Dewatering decanter centrifuges for tailing. Centrifuges are always one of GN’s popular products. In mining industry, they are mostly used in the tailing step for its efficiency in separating the extra solids particles. GN has large bowl centrifuges for this purpose.

Welcome to contact GN Directly for separation solutions.